Visionary Robots with AI Offer Human-Like Precision

Nigel Smith, CEO of industrial robot specialist TM Robotics, explains why a combination of 2D and 3D vision systems and artificial intelligence (AI) are among the latest technologies set to usher in a new phase of robotics.

With greater innovation and flexibility, many manufacturers are continually seeking to do more with robots.

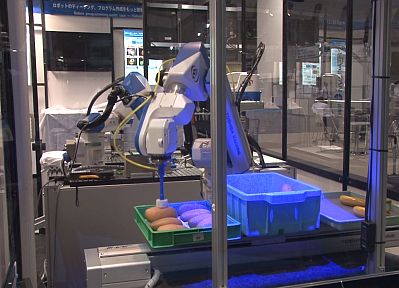

Robots equipped with 3D vision systems can be capable of human-like accuracy in tasks where shape or position are important.

Shops may be looking for smaller and more flexible designs that can fit easily into existing production lines, or for existing robots that are more easily repurposed and reassigned to tasks. In these environments, robots will need to become increasingly versatile around the production line.

Two of the growth areas will include industrial robots that operate and tend to CNC machines and robots used in welding applications.

One feature that will be crucial if robots are to perform these expanded tasks successfully: a 2D or 3D vision system. Unlike "blind" robots -- those without vision systems -- which typically complete simple, repetitive tasks, robots with machine vision can do much more by reacting intuitively to their surroundings.

Greater Precision

In the case of 2D vision systems, the robot is equipped with a single camera. This approach is better suited for applications where reading colors or textures is important, like barcode detection.

Shibaura Machine's vision system, TSVision3D, uses high-speed cameras and intelligent software to identify the exact positions of items.

3D systems, on the other hand, evolved from spatial computing developed at Massachusetts Institute of Technology (MIT) in 2003. Multiple cameras create a 3D model of the target object and are especially suited for any task where shape or position is important. That includes precision bin picking, one of the most sought-after tasks for robots.

Both 2D and 3D vision systems have a lot to offer. 3D systems, in particular, can overcome some of the errors 2D-equipped robots encounter when executing physical tasks, that would otherwise leave human workers with the task of diagnosing and solving the malfunction or resulting bottle neck.

Going forward, robots equipped with 3D vision systems have potential for reading barcodes and scanners, checking for defects in engine parts, inspecting packaging, checking the orientation of components and more.

Human-Like Reliability

According to Wendy Tan White, CEO of the robotics software company Intrinsic, "We're on the cusp of an industrial robotics renaissance, driven by software-first solutions, cheaper sensing, and more abundant data."

"Cheaper sensing and more abundant data." In other words, we can expect to see the focus of robotics shift beyond sensor device hardware towards building AI that helps optimize the use of these sensors and ultimately improves robot performance.

3D vision allows robots to account for unforeseen variables in their work environment, to complete more than one task without reprogramming and to be used in a broader range of applications.

That will include combinations of machine vision with learning capabilities. Take precision bin picking applications, for instance. With previous robot systems, professional computer aided design (CAD) programming was needed to ensure the robot could recognize shapes. While these CAD systems could identify any given item in a bin, the system would run into issues if, for example, items appeared in random order during a bin picking task.

Instead, advanced vision systems use passive imaging, where photons are emitted or reflected by an object which then forms the image. The robot can then automatically detect items, whatever their shape or order.

An example is Shibaura Machine's vision system, TSVision3D, which uses two high-speed cameras to continuously capture 3D images. With intelligent software, the system can process these images and identify the exact position of an item. Through this process, the robot can determine the most logical order and pick up items with sub-millimeter accuracy, with the same ease as a human worker.

With TSVision3D, we are seeing robot AI evolve to the point where it can interpret images as reliably as humans. This could, in the words of Wendy Tan White, bring us closer towards "an industrial robotics renaissance."

Want more information? Click below.

Rate this article

View our terms of use and privacy policy